Air Hammer Drilling

Air hammer drilling is a modernized version of rope drilling or agitator drilling, but with significant improvements to make drilling faster. In air hammer drilling, you still use the same drill rods that are taken out of the machine and inserted into the well, attached to the top of the air hammer. These drill rods receive the rotation of the rotating head or rotating disk and transmit the rotation to the air hammer. The rotation keeps the hole round and allows you to use a drill bit that will not completely fill the hole.

If you use a solid round drill bit, you will not be able to extract the cuttings from the bottom of the hole. Therefore, any drill bit you use must have the right shape so that the cuttings can be discharged from under it. Therefore, the drill bit must be rotated to maintain the round shape of the hole.

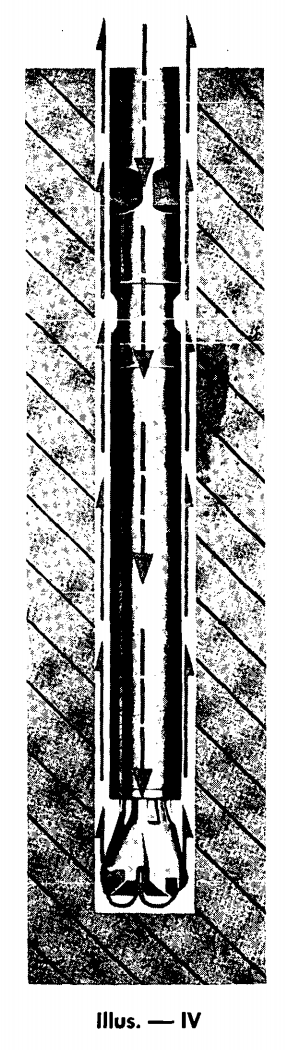

Again, as with air rotary drilling, the air is passed down the drill rod to the air hammer. The path of the air is similar to Figure 4, with the dotted arrows showing the air passing through the center of the drill rod, past the hammer, and then rising to the surface from the hammer and outside of the drill rod.

The actual drilling action of the hammer is caused by the piston inside the hammer pushing down, causing it to hit the top of the drill bit. The drill bit then impacts the formation. The air is then redirected through a valve mechanism to go under the piston, causing the piston to be lifted by the air. When the piston reaches the top of the cylinder it is in, the valve switches again, allowing air to enter above the piston, forcing the piston down for the next impact on the drill bit.

You might describe this as similar to placing a drill bit in the ground and then hitting the top of the bit with a sledgehammer. But here, you use air and a piston to achieve this hammering action. Although the designs of impactors vary, they all work on essentially the same principle, with the air pushing the piston down, lifting it up, and then pushing it down again.

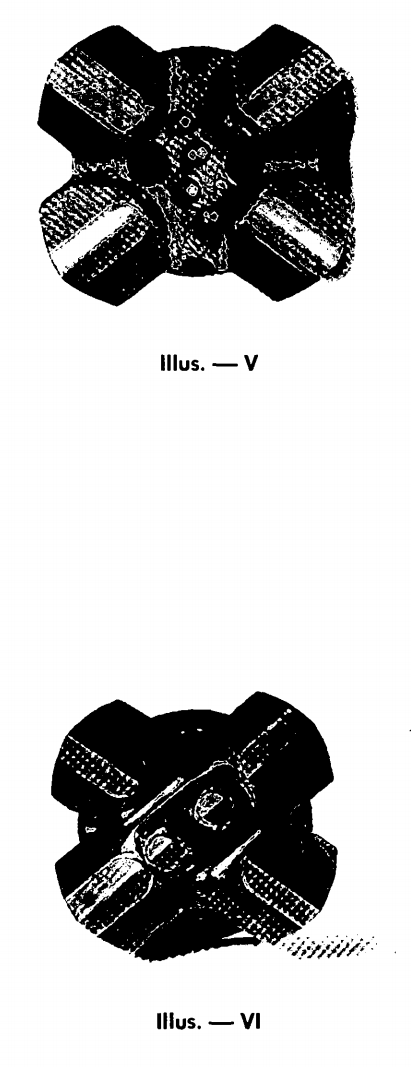

The drill bits used with impactors are interchangeable, so you can remove them from the impactor and sharpen them. Figure 5 shows an X-type drill bit, and Figure 6 shows an X-type sinking drill bit, a regular X-type drill bit, and a sinking ball-tooth drill bit. Drill bits work differently in different formations; therefore, each driller learns by trial and error which drill bit works best for his formation and then continues to use that type of drill bit.

As the impactor drills, the piston strikes the drill bit, which in turn strikes the surface of the formation being cut. However, the speed at which a drill bit rotates varies. These speeds range from 400 to 1,200 times per minute, depending on the specific hammer and its operating pressure. There is a great deal of debate as to which of the various brands of hammers and hammer operating pressures drills the fastest. I am sure you will find that conditions vary from one formation to another, and some drill bits will work better than others. But the working principle is the same.

As the drill bit impacts the formation, debris is knocked out, and the air exhausted from the bottom of the drill bit lifts these debris and carries them back to the ground outside the hammer and drill pipe. When the debris and/or dust is exhausted from the top of the well, the speed immediately drops because the airflow is no longer restricted. Therefore, the debris falls to the ground in the area surrounding the well. The finer the debris or dust, the farther it flies before falling to the ground.

After the hammer has bored the new hole to the same depth as the drill pipe it is connected to, drilling stops and the drill pipe is disconnected from the rotary head or kelly (depending on the type of machinery being used). A new drill pipe is then inserted between the existing drill pipe and the rotary head or kelly in the well. This way you can continue drilling to the additional depth of the new drill rod.

So as you drill deeper you simply add new drill rod. The depth that the machine can drill is limited only by the weight the machine can bear because as the hole gets deeper the number of drill rods increases and the weight of the machine gets heavier. In a wet hole the depth that can be drilled is limited by the pressure that the water exerts on the piston at the bottom of the hole. This pressure will eventually reach a point where it is equal to the pressure of the air injected at the top of the hole.

In introducing air rotary drilling and air hammer drilling, it is sufficient to say for now that when there is a lot of water in the well a practical point is reached where it is unprofitable to continue drilling deeper with an air drill because the weight of the water reduces the efficiency of the hammer.

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China