Cased Holes

In screen setting methods, first consider those used where the casing is advanced with the hole, as in cable tool, hollow rod, or jetting work. The casing may only be taken to the depth where it is planned to have the top of the screen. The screen is then lowered into the hole and bailed or washed into place below the casing.

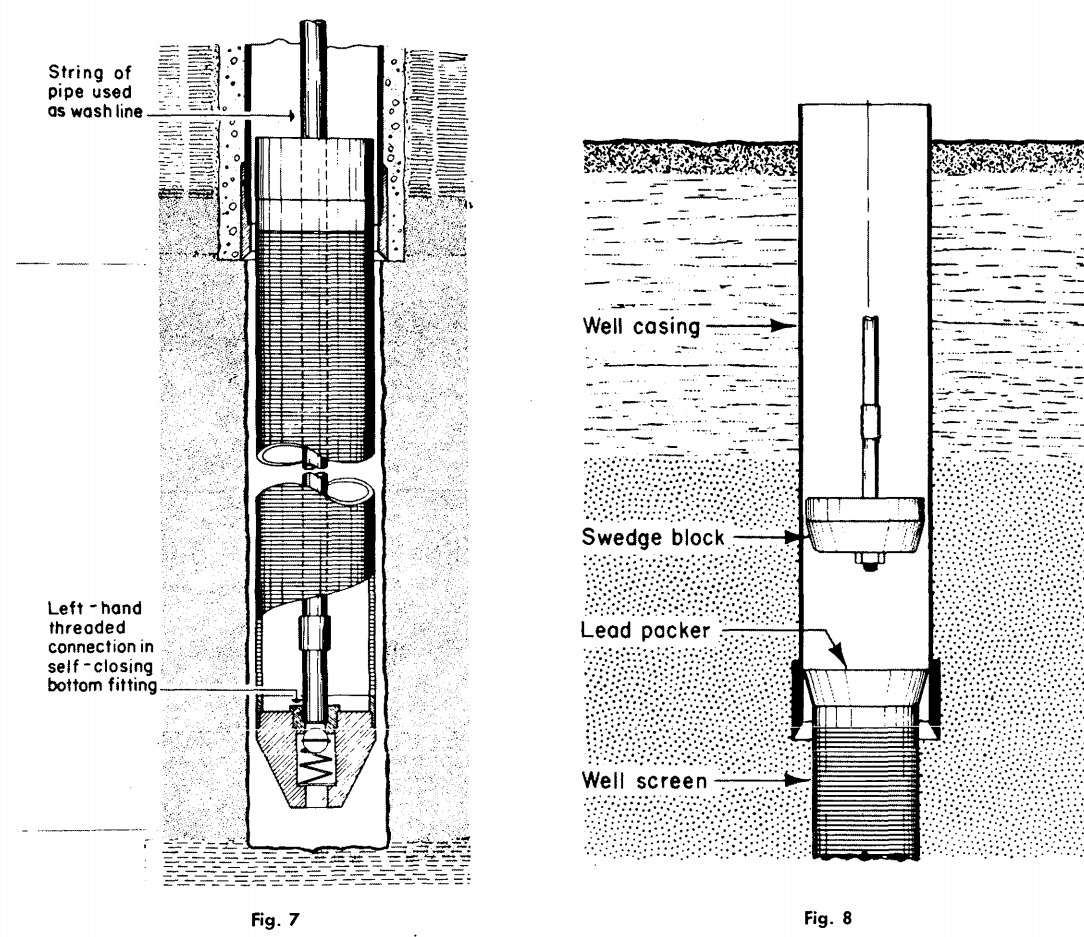

In some cases, an open hole may be drilled below the casing, and mud or clay is used to keep the hole open until the screen is lowered into place. In these procedures, it is necessary to know in advance the character of the formation. Such information is generally obtained by a test or pilot well, which precedes the permanent construction. Figure #7 shows a typical "jetting down" arrangement.

Another, and perhaps the most often used, method of setting a screen in a cased hole is the so-called telescoping procedure. Here, the casing is driven to the bottom of the formation or to the depth planned for the bottom of the screen. A screen is selected with a diameter that will fit inside the casing. It is then lowered to the bottom of the well, and the casing is bumped or jacked back to expose the screen.

In both of the above-described methods, the final step is to seal the top of the screen to the well casing. Traditionally, this is done by swedging out a lead seal at the top of the screen. A lead seal and a typical screen swedge are shown in Figure #8. More recently, at least one manufacturer has introduced a rubber-type screen top seal to the market. It is said to not only provide an effective seal but also lessen the possibility of electrolysis between, for example, steel well casing and bronze screen.

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China