Instruments Used

Time, water levels and capacity flow rates are three measurements to make during a pumping test.

Making accurate measurements together with the planned program of testing procedures will not only allow the contractor to properly select the pump best suited for the well, but also provide valuable information about the ground water aquifer below.

To measure these values the following instruments can be used:

Time

In the measurement of time, the common watch is all that is required for successful well testing.

It is important to record time during a well test since pumping levels change as a function of time.

This is more fully explained in the section "Conducting Well Tests."

Water Levels

To make readings to any water level, the simplest and also the crudest way is to use a heavy weight or float on the end of a steel tape or chalk line.

Readings taken in this manner often vary from two to six inches from true readings depending on the kind of line and whether or not the weighted end will float.

The most satisfactory method is to use either an air line or an electric circuit.

Measurements to the static or pumping level are always important and the use of an air line (or some other means more accurate than a weighted tape) are generally required.

Measurements to the pumping level are particularly important because they not only furnish the basis for estimating pumping levels for various capacities, but they also determine the power costs and the proper setting of the pump bowls if they are of the deep well turbine type.

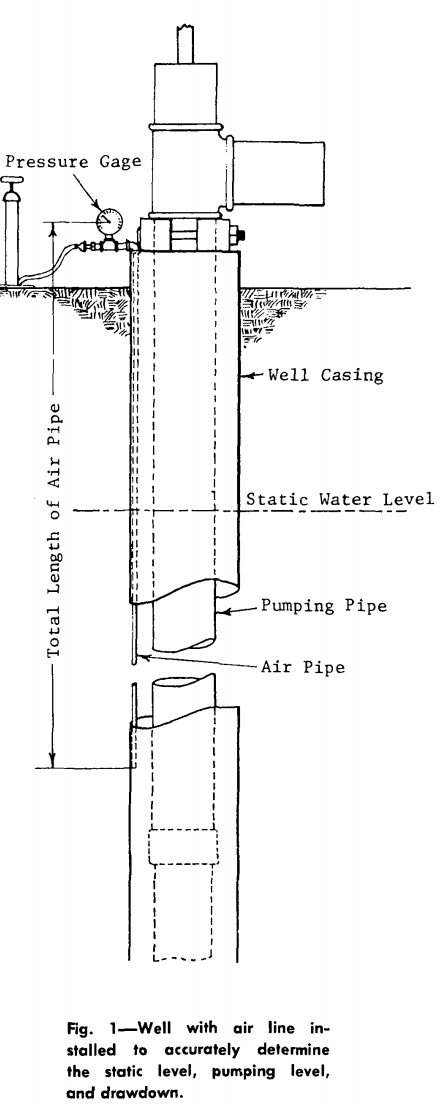

The illustration (Figure 1) shows a well in which an air line is installed to determine accurately the static level, pumping level and drawdown.

This apparatus is inexpensive, easy to install and remove and is generally accepted for all but the most accurate tests.

It consists essentially of enough small diameter pipe or tubing to extend from the surface well to a point below the static or pumping level depending on which is being measured.

On top of the tubing or pipe is an ordinary altitude or pressure gauge to which is attached a tire pump or air pressure when it is available.

Any small size of iron, brass or copper, 1/8 or 1/4 inch in diameter, may be used.

If the air line is to be left in the well for permanent use, it should be of some non-corroding metal; if jointed and coupled, the joints must be absolutely air tight.

Tubing is now commonly used for air lines.

Two things are necessary to make accurate readings with this device.

First, the exact vertical distance between the center of the pressure or altitude gauge and the open end of the air line as it is installed in the well must be determined.

This measurement is obtained by carefully measuring the air line as it is placed in the well.

With pipe this can be done accurately; with tubing it sometimes becomes a problem since the tubing has a tendency to curl.

For this reason it is necessary to take special pains with tubing to get the vertical distance accurately.

Second, the air line must be air tight from one end to the other, including the connections at the gauge and air pump.

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China