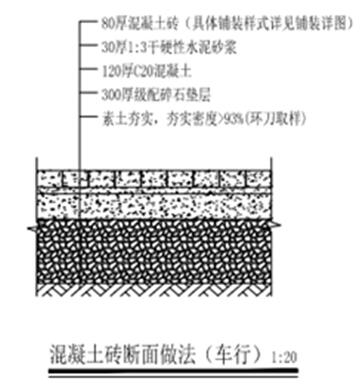

(1) Construction method

1) 80mm thick concrete bricks (see the detailed paving drawing for specific paving styles)

2) 30mm thick 1:3 dry hard cement mortar

3) 120mm thick C20 concrete surface layer

4) 300mm thick graded crushed stone

5) Compact the bare soil, compaction density>95% (ring knife sampling)

(2) Structural diagram

(3) Construction standard

1) The type and quality of concrete bricks used in the surface layer must meet the design requirements.

2) Concrete bricks should be classified by color, and those with cracks, corners and surface defects should be removed. Blocks with different numbers and types should not be mixed.

3) Joint adjustment and trimming: Use a wire to adjust the joints of the laid bricks, straighten the joints, and sweep out the excess mortar in the joints. Tap the bricks firmly. If there are broken bricks, they should be replaced in time.

4) Arrange the dimensions along the longitudinal and transverse directions of the pavement, and the seam width should not exceed 2mm. When the size is less than a multiple of the whole brick, half a brick can be cut for the corners; when the size difference is small, the seam can be adjusted.

5) The surface of the concrete brick surface layer is clean, the color is consistent, the joints are uniform, the periphery is straight, and the slabs have no cracks, corners, or missing edges.

6) The slope of the ground pavement meets the design requirements (and the minimum is not less than 0.3%), there is no overflow, no water accumulation, and the joints with the drainage outlet are tight and firm.

7) The size of the edging materials at the adjacent surface layer meets the design requirements and construction specifications, and the edges and corners are neat and smooth.

8) Interface with edge materials: Cut straight. For the cut materials at the straight joints, control at 45°, 1\4 pieces, and splice;

9) Curve interface processing: Control the smoothness and roundness of the arc. Do not allow obvious corners or protrusions. For the paving materials at the interface, cut isosceles with equal arc length. Do not allow single-sided cutting;

10) Inspection items

1 Surface flatness: Control within 2MM, check with a 2M ruler;

2 Straightness of seams: Control within 3MM, check with a 5M wire. If less than 5M, check with a wire;

3 Height check between adjacent panels: Control within 2MM

(4) Rendering

(5) Detailed nodes

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China