Orifice bucket

Orifice Bucket

The Illinois State Water Survey has developed a device termed an "orifice bucket" for readily measuring limited rates of flow up to about 180 gpm.

It consists of a small cylindrical tank or container with one or more one-inch holes accurately bored through the bottom.

The water to be measured flows into the tank and discharges through the one-inch orifices.

The container fills with water to a level where the pressure head causes the discharge through the orifices to just equal the inflow.

A gauge glass or a simple Piezometer tube is connected into the wall of the container near the bottom.

A suitable vertical scale is fastened to the outside so that the orifices can be read accurately.

A calibration curve shows the rate of discharge through a single one-inch orifice for various values of the pressure head.

The flow rate taken from this curve multiplied by the number of orifices used gives the total rate of discharge through the device.

Table 2 shows the rating curve for a one-inch orifice as determined in the Water Survey laboratory.

It shows, for example, that when the water is 16 inches deep in the container, the flow through one hole is 14.4 gpm.

If the bucket used is made with five holes, the total rate of flow with 16 inches of pressure head would be 72 gpm.

One of the practical uses of the orifice bucket is for measuring the discharge from a plunger pump or rig-operated pump where the flow is not constant.

Drop Measurement

One of the least accurate measurements of flow that can be employed is that of the "drop method."

The principle employed in this method relates to the velocity of the water passing through a discharge pipe either in full or partial flow.

While not a desirable means of measuring the capacity, there will be times in every well and pump installer's employment that a measurement of capacity is desirable at a time when no field instruments are available.

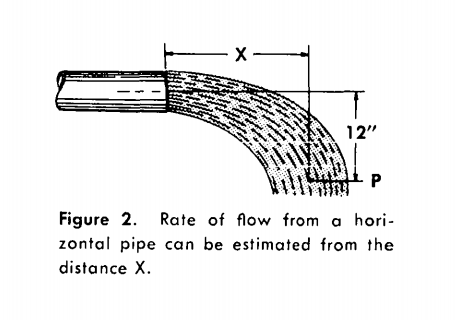

In such instances, measure the horizontal distance from the end of the discharge pipe that is required to allow the center of the discharge stream to fall 12 inches. (See Fig. 2)

The horizontal measurement in inches can then be converted to gallons per minute by entering Table 3 when the diameter of the discharge pipe is known.

Limitation in the use of this table is to measuring only discharge pipes that are full.

Tables are available for partially filled discharge pipe and can be found in many water well handbooks.

In addition to the "Drop Method" of measuring capacity, other approximating methods of measuring flows and well yields are common to the industry.

Among them is the "Bailer Test" which involves rapid bailing of the well, measuring the drawdown and by counting the bailer loads over a measured time period, calculating the average flow.

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China