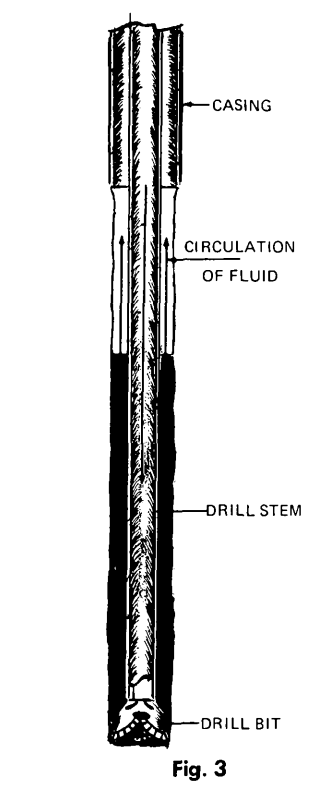

The next principle is the drilling of the actual hole. We begin by allowing the drill string to penetrate the formation which consists of a rotating or revolving of the drill tools and concentrically pumping the drilling fluid through the hollow string. This allows the fluid to discharge out of the bit and circulate to the surface. The viscosity or thickness of the drilling fluid will carry the cuttings to the surface due to the velocity. The construction of the mud ditches on the surface reduces the velocity and thereby allows the cuttings to settle. This enables us to reuse the fluid over and over again. It is very important that the sand or cuttings settle in the slush pit to prevent the pump from circulating high volumes of cuttings which will cause excessive wear in the pumps.

Rotary drilling, as previously stated, consists of the removal of formations by pumping a drilling fluid through a string of hollow tools removing the formations encountered by the bit. The principle of water well drilling is to construct a plumb or straight hole. In rotary drilling this is accomplished by not running a slack line. In other words we must not allow the full weight of the string to apply upon the bit. If this should happen we will cause a bow in the line of tools and thereby cause the bit to wander or move in a direction other than plumb. The proper way to maintain a straight or plumb hole is by the use of drill collars in deep holes. A drill collar is a section of very heavy wall pipe that consists of considerable steel which allows weight to be exerted directly upon the bit and also causes the string to be pulled taut or plumb. In order to get the designed penetration from the bits used we must apply a certain force or pounds per square foot of area drilled. In other words a certain force is necessary to penetrate the formations. From the driller's manuals we see that pressures vary depending upon formations encountered.

It is very important to mentally visualize the formations encountered. This must be done by the drilling or reaction of the machine itself. This is a matter of experience from the watching of the machine operate in various formations. Sand, for instance, will tend to cause a chatter and drill rather fast; while clay will cause the machine to run rather smooth and drill slow. Other than this we find the drilling procedure to be a combination of varying drilling conditions. This varying speed of the drilling vs operation of the machine through experience will enable the driller to determine the formations penetrated.

In recent years the use of the electric log enables us to confirm various formations penetrated to a much greater degree than before. The types of pumps used in the drilling depends upon the formations and depths to which the drilling will be done. A centrifugal type of pump will allow us to have rather high volumes of fluid to relative shallow depths but is limited when the friction loss in the drill pipe becomes high due to long lengths or small size. When drilling to deep depths it is necessary that high pressure piston pumps be used. They do require careful design of the mud pits together with good mud control to prevent high sand contents in the fluid. High volumes of sand in this type of pump will cause rapid wear of the pistons and liners.

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China