Rotary drilling

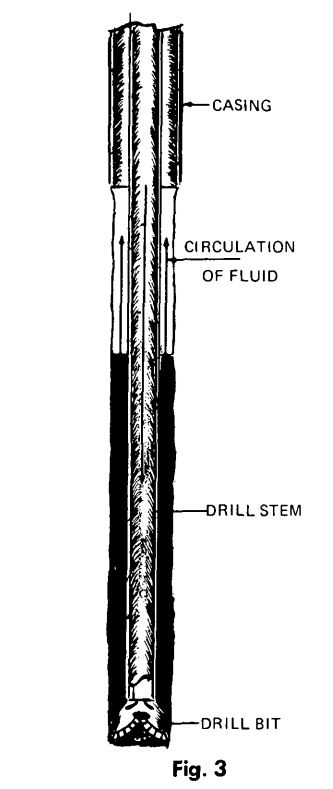

The idea of rotary drilling was to create a hole in the earth by circulating fluid out the end of a hollow string of pipe washing the cuttings back to the surface. This principle worked very well until the formations encountered began to take or absorb more water than was being pumped down the drill stem. This presented a problem of loss of circulation. Many methods of overcoming this problem were tried and as a general solution a mixture of clay and water was used to seal the formations and prevent water loss. In early construction, drillers would locate a clay bank from which they would secure enough clay to make a slurry which would prevent the loss of the drilling fluid (Fig. 3). This principle was employed until the present method of rotary drilling was established.

It consists of a drilling machine which has a hoisting rig which usually has two drums. The principle of this type of drilling involves the use of hollow drill tools through which a drilling fluid, consisting of refined clays in a mixture of water, is circulated. As previously stated the main purpose is to remove or float the cuttings to the surface. Once the fluid is at the surface its velocity is reduced to allow the settling of the cuttings in the mud ditch thereby allowing the reverse of the fluid for the further removal of cuttings. We have, therefore, arrived at the general principle of rotary drilling. We must now begin to explore the principles which enable us to construct a successful well by this means.

The first order of business is to have a machine capable of drilling to the depth and diameter contemplated. Then it is important we level the machine to allow the drilling of a vertical hole in which we may set our casing and work. The machine will allow the operator to perform this function. We must realize that if the machine is not level then we tend to have a drill hole which will not follow a plumb and vertical line. Immediately upon the beginning of the set up we must begin to prepare the drilling fluid. This is very important as with the modern fluids they require a time for swelling. If they are used before the time necessary we tend to pump or place undeveloped fluids opposite formations - thereby creating a situation which will allow them to swell in place. The modern clays for drilling require curing time and therefore if ignored they tend to cure in place. If this happens we can see what happens when we attempt to develop the formation. I only mention this and attempt to emphasize at the beginning how important it is to prepare this drilling fluid before using same.

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China