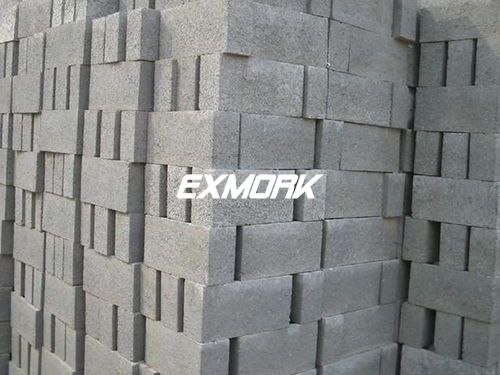

Cement bricks are a new type of wall material made by mixing cement, fly ash, stone chips, gravel or slag and other waste materials, extruding and curing. They are environmentally friendly and energy-saving bricks.

Cement bricks have the characteristics of large shrinkage and self-shrinkage. Since the bricks are not sintered, they have some active materials in themselves, so their stability is far less than that of sintered bricks. In addition, their shear strength is far less than their compressive strength, and they are brittle and hard. Therefore, walls built with them often have oblique cracks and vertical cracks. In addition, the surface of cement bricks is smooth and delicate, and they are prone to hollowing, cracks and other quality problems after plastering. Cement bricks are a new type of wall material. They have just begun to be promoted and applied in some areas, and many problems have arisen in their use. Based on the engineering experience of cement bricks that have been used, we have summarized the use methods and precautions of cement bricks.

1. Requirements for the use of materials

(1) It is strictly forbidden to use cement bricks with insufficient curing age. The curing age of cement bricks should be no less than 28 days. After the curing age expires, there should be a storage period of no less than 1 to 2 weeks. This stage is the main completion stage of the shrinkage and self-shrinkage of cement bricks. To ensure the safe use of cement bricks, it is best to store the bricks on site for more than 1 to 2 weeks after leaving the factory before using them. Of course, the longer the storage time of cement bricks, the safer they are to use. Cement bricks must be accompanied by a factory certificate when leaving the factory, and random sampling and witnessing on-site sealing must be sent to the laboratory for physical performance index inspection. Only after passing the inspection can they be used in the project.

(2) Mortar for masonry of cement bricks. Cement-lime mixed mortar should be used for masonry mortar of cement bricks. Micro-foaming agent mortar prepared with micro-foaming agent is strictly prohibited, and the strength grade of the mortar should not be less than M5. The workability and operability of the mortar should be better than the masonry mortar of general sintered bricks.

2. Requirements for masonry operation

(1) When using cement bricks for masonry, the "three-in-one masonry method" (i.e. one brick, one shovel of mortar, and one squeeze and knead) should be used; the mortar should be full and the mortar adhesion rate should be above 85%. Avoid using the mortar-laying brick method for masonry; the bricks should be soaked the day before masonry at room temperature.

(2) Treatment of brick joints. Cement bricks have a smooth surface, which is not conducive to surface plastering, so measures should be taken during masonry to compensate for it. The method is to treat the brick joints during masonry: that is, the brick joints are scored into concave joints (seam depth ≥ 5 mm). After the joints are scored, the wall surface can be cleaned with a broom. Sweeping can make the wall surface clean on the one hand, and roughen the surface of the scored mortar joints on the other hand.

(3) Maintenance of brick walls. The masonry wall can be sprayed with water for 3 to 4 days depending on the weather conditions.

3. Requirements for cement brick wall plastering

It is best to plaster cement brick walls after the brickwork is completed and the load has been dropped for no less than 10 days, and pay attention to the following points.

(1) Spray water on the wall to moisten it one day before plastering. The water spraying should be uniform and no leakage or excessive water spraying should be allowed.

(2) Before plastering, anti-cracking mesh should be laid as required at the intersections between the wall and concrete beams, columns, flues embedded in the wall and other foreign materials, and at the concealed pipe grooves.

(3) Before plastering, a layer of plain cement slurry should be brushed on the brick wall surface, and then plastering should be done immediately. Plastering should be done in several layers in strict accordance with the design and specification requirements. It is strictly forbidden to do it in one layer. The thickness of each layer of plastering should not exceed 10 mm. This is because cement brick walls absorb water slowly. If the plastering is too thick at one time, it will cause the plastering mortar to fall, resulting in falling cracks on the plastered wall surface, and hollowing of the plastering layer will often appear at the cracks. The interval between layered plastering is generally after the last layer of plastering mortar has initially set and absorbed water.

(4) It is strictly forbidden to use cement paste to scrape and smooth the surface of cement brick wall plastering. To prevent cracking of the plastered wall, the surface

is preferably smoothed to a fine and straight surface. The method is to use a wooden trowel to smooth the surface of the mortar when the mortar absorbs water and presses out a fingerprint with your fingers, then use a steel trowel to press the sand particles down to make the wall surface a fine and rough surface. If the operation is difficult, you can also smooth the wall surface and immediately wipe the wall surface with a sponge dipped in clean water to make it a fine and rough surface.

Contact: Exmork

Tel: 86-15757781695

Whatsapp: 86-15757781695

Email: exmork@exmork.com

Add: Headquarters Economic Park,Yueqing,Zhejiang,China